Founded in 1919 in Columbus, Indiana, Cummins (CMI) is the largest dedicated global industrial diesel and natural gas engine manufacturer.

The company’s primary markets are highway & heavy-duty vehicles, construction, and general industrial markets, where it serves customers such as Chrysler, Daimler, Volvo, PACCAR, Navistar, CNH Global, Komatsu, and Ford.

The company’s products are sold in more than 190 countries via its network of 500 company-owned and independent distributor locations and over 7,500 dealers.

Roughly 55% of Cummins’ revenue is generated in North America, but China (10%) and the Asia Pacific (10%) are also meaningful markets. In fact, Cummins has had a presence in China and India for more than 40 and 50 years, respectively.

Cummins operates in four segments, and its largest sales driver is its engine division:

- Engines (34% of revenue, 40% of operating profit): builds diesel and natural gas engines for heavy-and medium-duty truck, buses, recreational vehicles, as well as light-duty automotive, agricultural, construction, mining, marine, oil and gas, rail, and governmental vehicle markets.

- Distribution (27% of sales, 16% of operating profit): distributes parts and filtration products as well as maintenance, engineering, and product integration services to end-users around the world.

- Components (23% of sales, 32% of operating profit): supplies products which complement Cummins’ Engine and Power Systems segments, including aftertreatment systems (used to convert engine emissions of criteria pollutants into harmless emissions), turbochargers, transmissions, filtration products, and fuel systems to help customers meet regulatory emission requirements.

- Power Systems (16% of sales, 12% of operating profit): sells power generators and systems (including controls, alternators, switches) for a diverse array of end markets, as well as high-horsepower engines for industrial applications.

Business Analysis

Cummins has built itself into the dominant truck and bus engine maker thanks to its expertise in meeting mandated emission requirements (the EPA has forced a 90% reduction in emissions in past decade) through innovations such as natural gas engines, hybrid buses, turbochargers and advanced catalytic systems.

This has led to dominating both the medium and heavy duty truck segment in North America, where the company has over 35% market share and is significantly larger than its nearest rivals.

The engine market has several barriers to entry that have helped Cummins build strong market share positions around the world. Extensive regulations have resulted in strict standards governing emission and noise, for example.

The engines Cummins’ manufactures need to comply with emission standards established by the European Union, EPA, the California Resources Board, and other agencies. Cummins spent more than $170 million on research and development in 2007 and 2008 in order to comply with 2010 EPA emissions standards in the U.S.

Notably, several of Cummins’ competitors opted to exit certain markets rather than pony up the cash required to remain compliant with their technologies. For example, Caterpillar exited the on-highway truck engine market in 2009, reinforcing Cummins’ technological lead.

Gaining entry to the engine business is very difficult. For example, PACCAR (PAC) launched its first line of engines less than a decade ago after spending around 10 years of time and more than $1 billion developing it. The finished engine even used some of Cummins’ own engine components.

Over the last decade, more than half of the $2 billion to $3 billion Cummins has spent on research and development has been invested in technologies that reduce emissions. When it comes to fuel-efficient technology, Cummins has established itself as the clear manufacturer of choice.

Beyond its engine intellectual property and economies of scale, Cummins’ moat is also formed from the way its business is operated. The company generally maintains long-term price and engine supply agreements with core customers.

The customer benefits from knowing Cummins’ products will be available, and OEM customers can collaborate with Cummins to jointly engineer future vehicles. In other words, switching costs are created that make it more difficult for new entrants to steal market share away from Cummins.

Engines are extremely important systems to keep heavy vehicles and equipment running, too. Idled trucks or heavy equipment can cause significant losses for their operators, so buying big ticket items like engines from a reputable vendor is critical. In most cases, it’s not worth the risk of switching suppliers for a customer to save a little bit of money.

Simply put, machine downtime from a faulty engine is extremely costly, reinforcing Cummins’ value as a premium engine supplier. Besides its technology advantages, Cummins’ large dealer network is especially important for its core customer base of medium and heavy-duty truck drivers, who travel long distances across the country each day.

Cummins’ vast network of dealer locations (over 7,500 across 190+ countries and territories) means it can provide much more timely aftermarket repair services, further gaining customers’ trust.

It’s also worth noting the complementary nature of Cummins’ technologies and distribution channels, which should continue unlocking growth opportunities for the business.

For example, Cummins was able to apply its base technologies to enter the light-duty engine market in the mid-2000s. On the other end of the spectrum, Cummins developed a 4,000 horsepower “Hedgehog” engine a few years ago that is designed to serve the locomotive market.

Through continuous innovation and growth of its distribution and dealer networks, Cummins can continue maintaining its market share and expanding into adjacent markets for long-term growth.

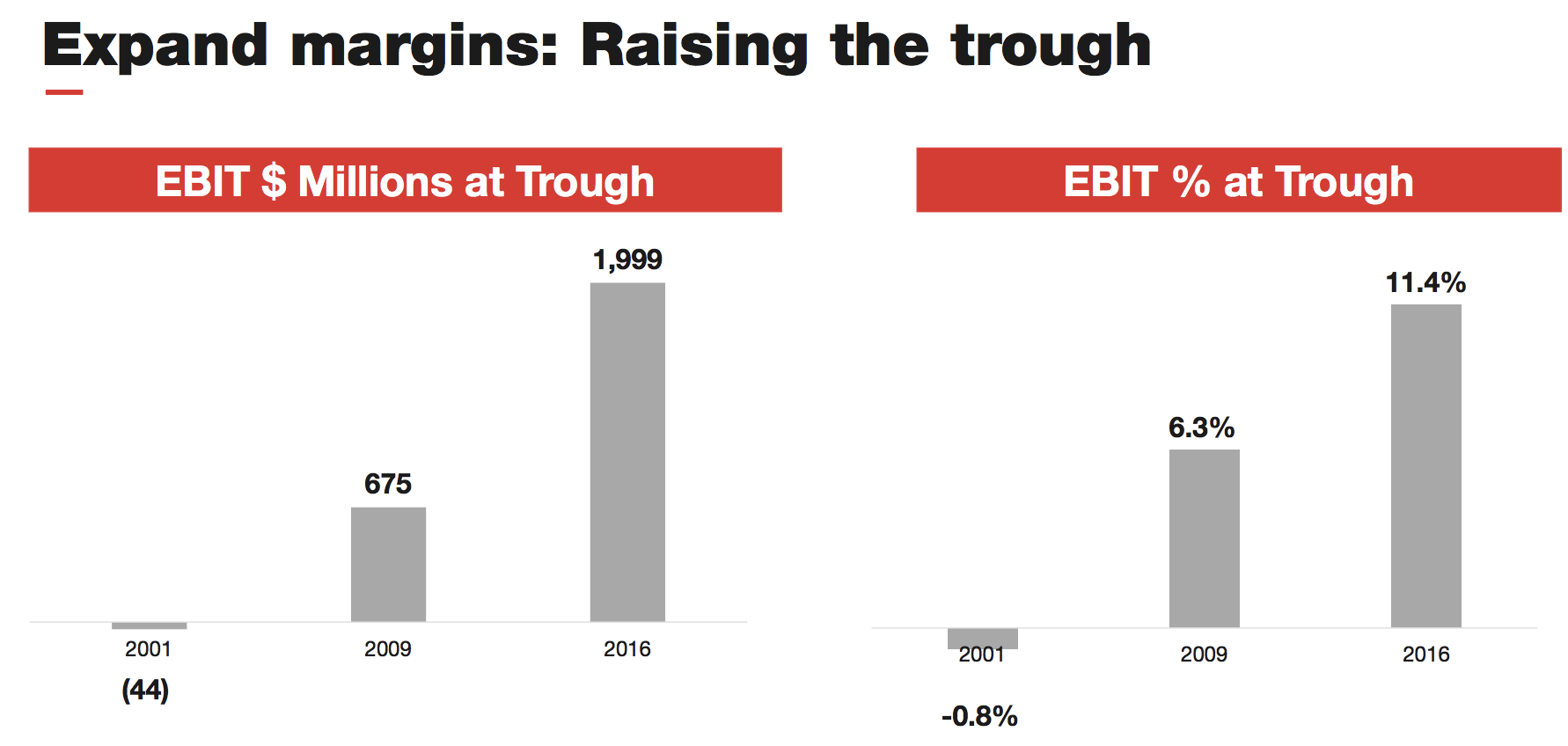

Despite Cummins’ numerous strengths, industrial companies are typically cyclical. Cummins is no exception and is very sensitive to new truck orders and the health of the global economy. When sales volumes drop, the high fixed costs required to run Cummins’ factories quickly eat into the company’s profit margins.

Fortunately, management’s restructuring initiatives, cost management, and manufacturing footprint adjustments over the years have helped the company improve its performance during inevitable industry troughs. However, investors should note that this can be a very volatile business.

Despite the cyclical nature of the business, Cummins has done a great job conservatively managing its business, which has allowed management to pay uninterrupted dividends for more than 25 years. However, there are still a number of risks to consider.

Key Risks

Like all multi-global corporations, Cummins faces the threat of a strong dollar. Negative currency effects reduce the sales and profits Cummins reports for accounting purposes and can create a growth headwind as the company attempts to gain more market share overseas.

As previously mentioned, the cyclical nature of the truck market can also cause short-term challenges for the company. Many industrial markets that depend on favorable commodity prices (mining, energy, etc.) are also big users of Cummins’ engines and experience peaks and troughs in demand.

While cyclical end markets and currency volatility ultimately seem very unlikely to threaten Cummins’ long-term earnings power, increasing competition could. Volkswagen took a 17% stake in competitor Navistar (NAV) in 2016 as it attempts to appease global regulators after its recent emission scandal by investing in low emissions vehicles, for example. Navistar and Volkswagen are investing to develop new engines and electric trucks, which are expected to launch by early 2020.

Additionally, a major customer (for more than 70 years), PACCAR, announced its entrance into the Class 8 engine market in 2010.Investors should continue watching Cummins’ cost-conscious truck manufacturers and OEM customers, who have historically outsourced certain types of engine production to Cummins but might look to vertically integrate more in the future to save money.

Cummins’ long-term contracts with its customers, the industry’s high level of emissions regulations, the importance of a big dealer network, and the costly and lengthy time required to develop an engine reduce the likelihood of this becoming an issue. However, it would be a material development as Cummins’ top four customers account for 33% of its total revenue.

Up until now, Cummins has benefited from the fact that increasing regulatory pressure to cut truck emissions has resulted in increasing design costs that potential rivals, such as Caterpillar (CAT), which used to have 35% of the market, chose to forgo by conceding the market to Cummins.

However, now well-capitalized rivals could start to eat away at its market share and reduce its pricing power if their own emission offerings prove a worthy rival to Cummins’ technologies, or if manufacturers increasingly vertically integrate.

Regulations could also prove to be a double-edged sword. Specifically, momentum seems to be building to ban the use of diesel-powered vehicles. Mayors of Athens, Madrid, Paris, and Mexico City have already announced they plan to implement a ban on the use of these vehicles in their cities by 2025.

Germany has also adopted legislation to ban new internal combustion engine vehicles by 2030, and China is considering adopting a ban on the production and sale of diesel-powered vehicles as well. Meanwhile, California government officials are calling for the state to phase out sales of diesel-powered vehicles by 2040.

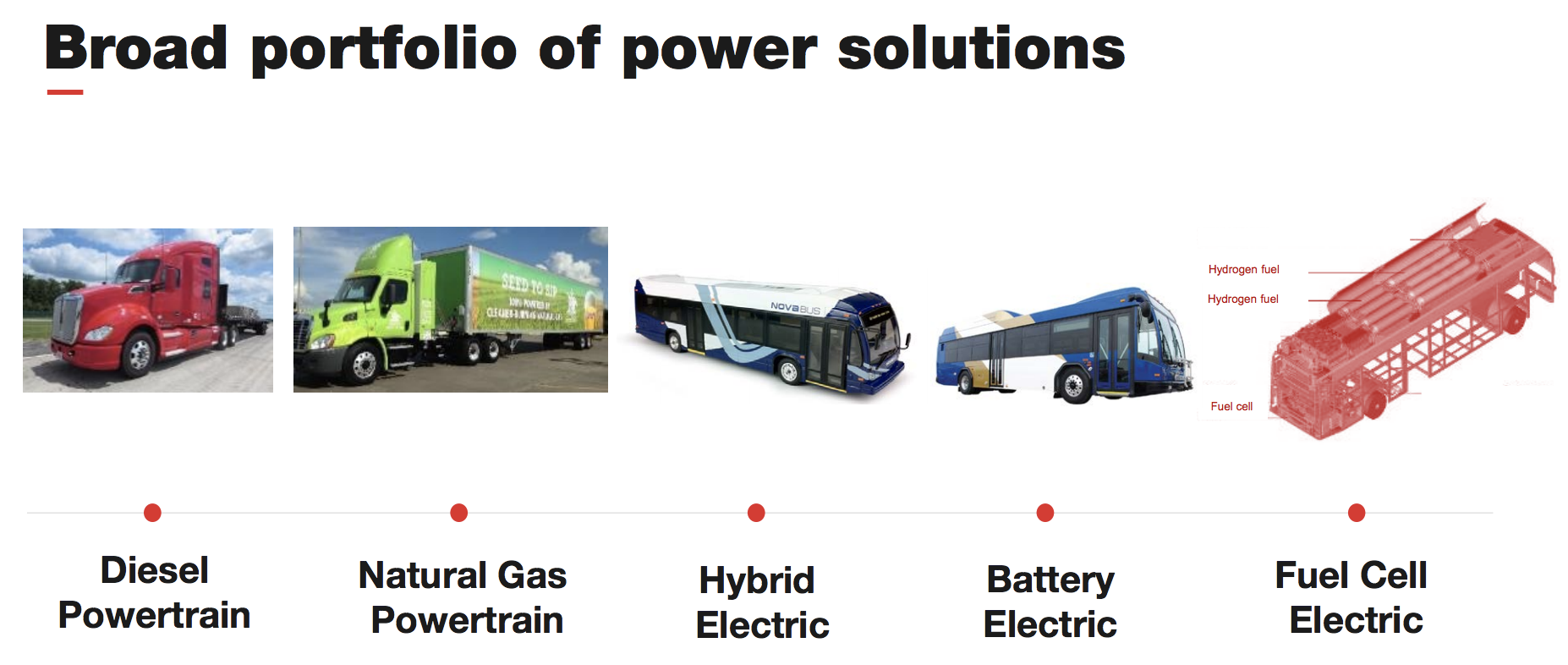

In other words, it’s not out of the question that Cummins will need to meaningfully evolve its business mix over the next decade or two. Fortunately, Cummins has not been resting on its laurels and has been working on natural gas, hybrid and electric engines for many years.

The company plans to invest another $500 million over the next three years to develop an electrified powertrain product line, along with key component technologies and service offerings to support electrification. Cummins plans to break out its electrification business as a separate segment later this year to provide even greater transparency behind its efforts to adapt for the long term.

However, companies such as Tesla (TSLA), Mercedes, and others have announced that they are working on electric semi-trucks as well. Tesla officially unveiled its all-electric truck in November 2017.

Tesla’s truck is expected to hit the market in 2019 and have enough range to cover most regional freight deliveries while being cheaper to operate than diesel trucks. Cummins announced its own electric truck (the company would primarily provide the battery and driveline system) in 2017 as well and doesn’t believe Tesla’s truck is suitable for long-haul trucking.

While the technology to create sufficiently long-haul electric semis is probably still at least a decade or two away, investors need to keep in mind that electric trucks could potentially impact Cummins’ business model.

That’s because electric vehicle engines are far more reliable, longer-lasting, and have very few moving parts. This makes for far less frequent maintenance requirements and would reduce demand for most of the equipment Cummins has spent the last century perfecting.

Closing Thoughts on Cummins

Cummins is a cyclical but solid blue chip dividend growth stock with an excellent record of rewarding income investors with secure and growing payouts.

Over the short term, investors need to remain mindful of the company’s volatile end markets, which can create attractive buying opportunities when times are tough. Cummins’ markets should continue growing over long-term periods, but the rise of electric vehicles and new rivals could alter the industry’s competitive dynamics.

For now, Cummins’ key competitive advantages (long-standing industry relationships, massive dealer network, economies of scale, technology investments) seem likely to ensure that the company adapts as needed and continues to capture a meaningful part of the market.

To learn more about Cummins’ dividend safety and growth profile, please click here.

Leave A Comment